TeSys

Production Test

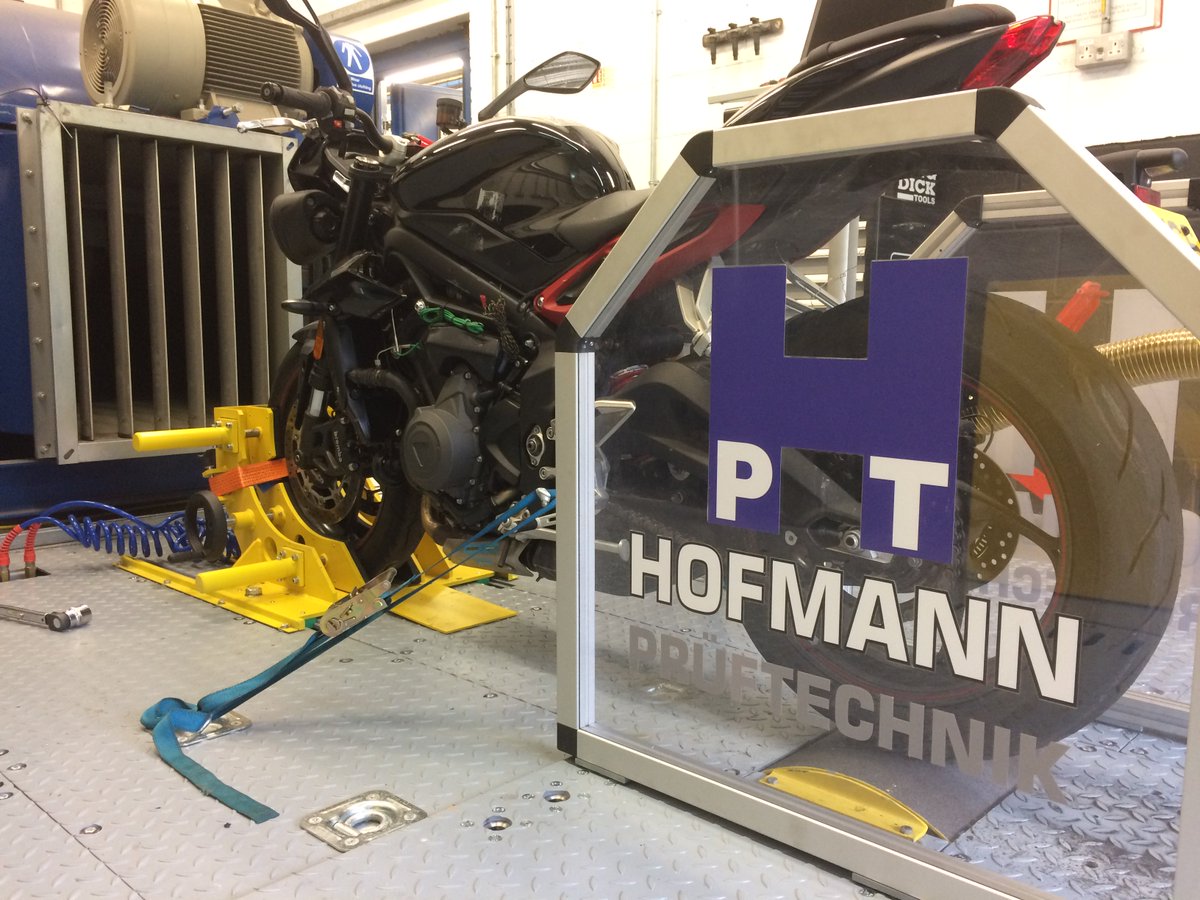

TeSys are able to offer a full range of Production test facilities for vehicles of all shapes and sizes:

- End of Line Brake test facilities to confirm ABS-, EDS-, ESP- and ASR.

- Contact or Non-contact wheel alignment Machines for toe, camber and caster

- Manual or fully automatic headlight Test & Adjustment, Bump and Steering angle.

- Vehicle Identification and electronic systems check out

- Complete end of line solutions are available for a full range of vehicles including Passenger Car, Commercial Vehicle, Motorcycles and Industrial/Agricultural/Specialist

Research & Development

World class control algorithms coupled with innovative mechanical designs provide a strong platform for the complete range of Research and Development Chassis Dynamometers and Ancillaries.

TeSys have experience in providing a complete range of Roll test equipment. From simple low capacity two wheeler motorcycles to high capacity multi axle special application vehicles – TeSys has a solution to meet your requirements.

NI PAtools

Intelligent Test Stands for the Automotive Industry

Modern cars have become "rolling computer networks". Numerous control units with sophisticated software assist the driver, but also demand accurate test systems with powerful and flexible software tools.

PAtools TX is the answer to this challenge: a modular software suite with configurable components for test parameterization, sequential flow control and data management. With PAtools TX, the test stand becomes part of the corporate IT-infrastructure and an integral part of the development process.

Adaptive procedures optimize engine maps and shorten test cycles. Automotive components not yet available are simulated using real-time models.

As a turnkey solution provider we plan and implement test stands for engines, transmissions, turbochargers, catalytic converters or chassis components as well as chassis dynamometers for the entire vehicle. Our experienced project teams support you during the automation or modernization of your existing test systems or planning of your next-generation test stands.

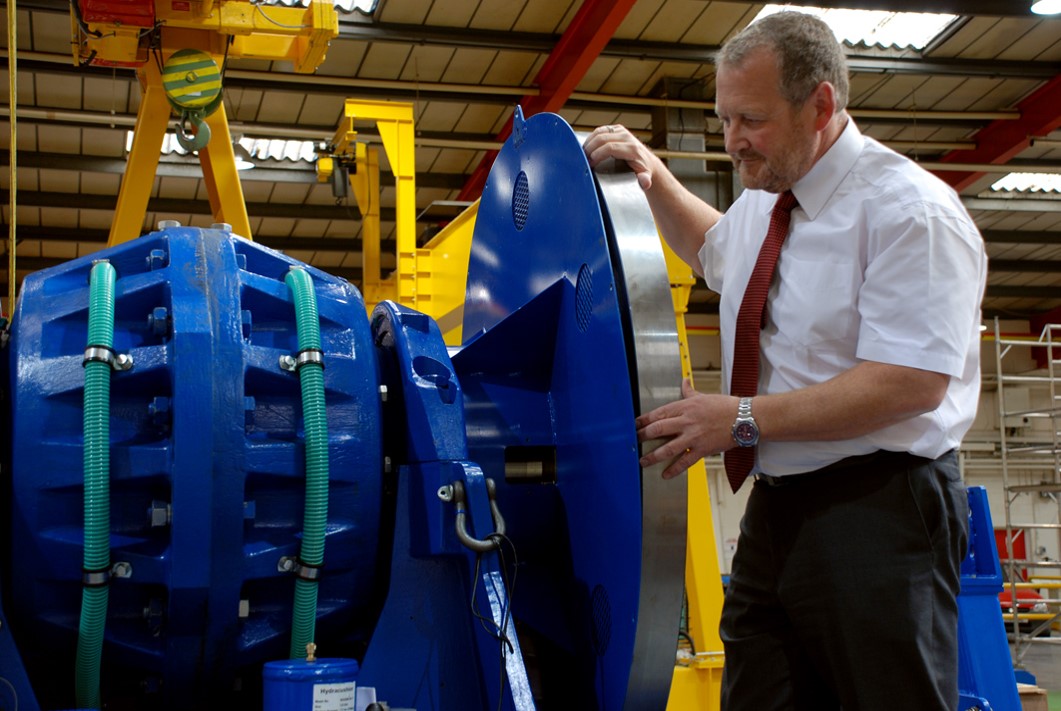

Froude

Froude designs, manufactures and supplies an extensive range of engine testing systems in the automotive, gas turbine, marine and industrial markets. Our test systems consist of a variety of engine and high technology control and data acquisition software, along with test stands and ancillary equipment for the test cell. Froude dynamometers are renowned the world over as offering exceptional high quality, reliable, and accurate test equipment which will provide a return on your investment for many years.

We produce customized solutions for our customers to ensure their engine test requirements are met, designed by our mechanical, electrical and software applications engineers. Customer requirements are discussed extensively with our technical sales managers at the start of any project to develop an optimum engineered solution and our team of installation and commissioning engineers will be on hand to deliver the final test facility on site.

We have two manufacturing and support centers — Froude, Inc. in Novi MI USA and Froude, Ltd. located in Worcester UK. Both facilities manufacture the complete range of hydraulic, (water brakes) eddy current, and AC dynamometers as well as the Go Power line of portable engine dynamometers. In addition to our range of test cell solutions, Froude offers dynamometer refurbishments, spares, repairs and maintenance contracts within our Customer Service plans.

Aerospace & Gas Turbine

Froude has always been the innovator of the test equipment industry producing world-class products for world-class customers. We design and manufacture a range of dynamometers, control and data acquisition systems and test equipment specifically designed for the discerning world of Gas Turbine testing.

Applications include research and development, production and post overhaul testing, with products in use with and being the product of choice by most of the world's leading manufacturers, M.R.O.s and test facility suppliers.

Froude has a unique range of dynamometers covering applications from high-powered industrial gas turbines, direct and indirect drive turbo shaft engines, turboprop engines and A.P.U.s. We are able to supply hydraulic (water brake), eddy current and AC dynamometers for a wide range of gas turbine engine testing applications.

Engine

Froude is one of the world's leading suppliers of engine testing systems.

We are able to offer one of the most comprehensive range of eddy current, hydraulic (water brake) and AC dynamometers available for automotive, heavy duty and industrial diesel engines. Together with our Texcel digital control and data acquisition systems, we can provide solutions from simple overhaul test applications through to high level research and development facilities.

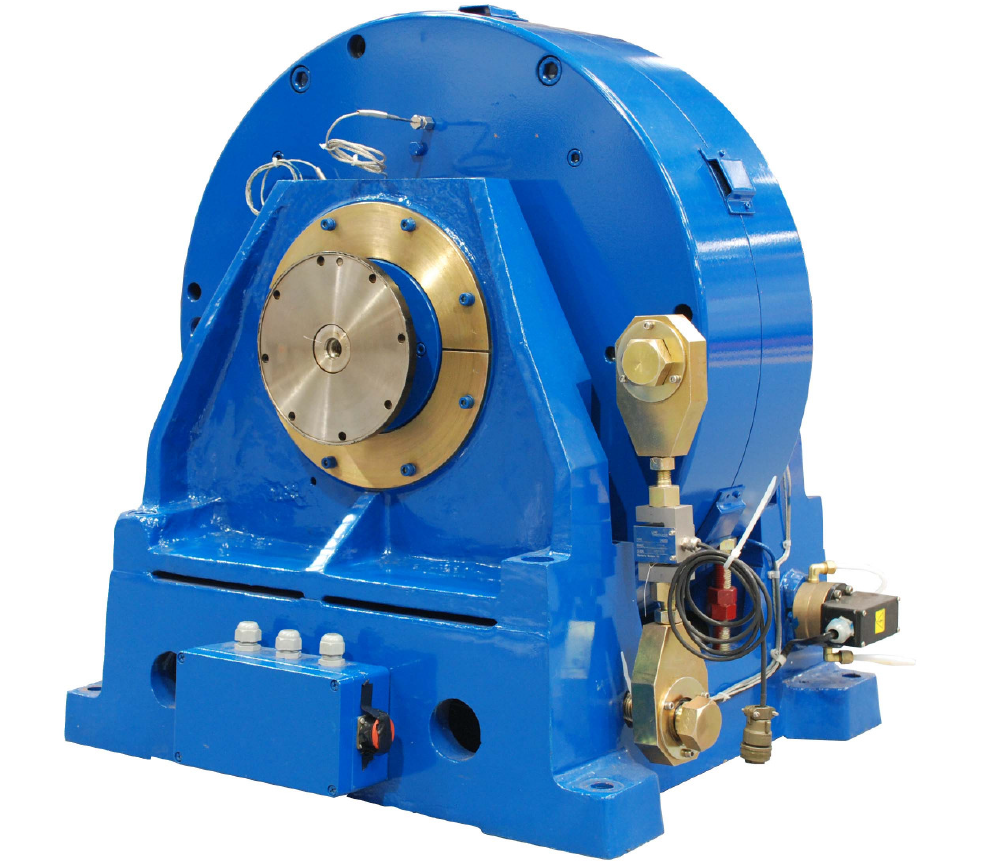

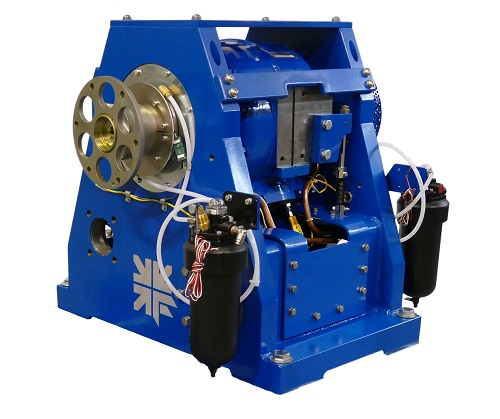

Hydraulic Dynamometers

The Froude F Range Hydraulic dynamometers (also referred to as water brakes) have been designed to be compact, robust and to allow easy maintenance. Some of these models are available with a streamlined, fabricated base. This base is not only ultra durable due to the powder coating process, but also offers flexibility with water inlet/outlet placement and lifting eye locations.

These engine dynos are fitted with two half couplings which, with the rotor, are oil injected onto the shaft. The standard machines run in grease lubricated rolling element bearings.

The hydraulic dynamometer working compartment consists of special semi-circular shaped vanes cast into stainless steel rotor and stators. Water flowing in a toroidal vortex pattern around these vanes creates a torque reaction through the dynamometer casing which is resisted and measured by a precision load cell. The dynamometer load is controlled by a 'butterfly' water outlet valve, operated by a closed loop electro-hydraulic servo system. The power absorbed by the dynamometer is carried away by the water in the form of heat.

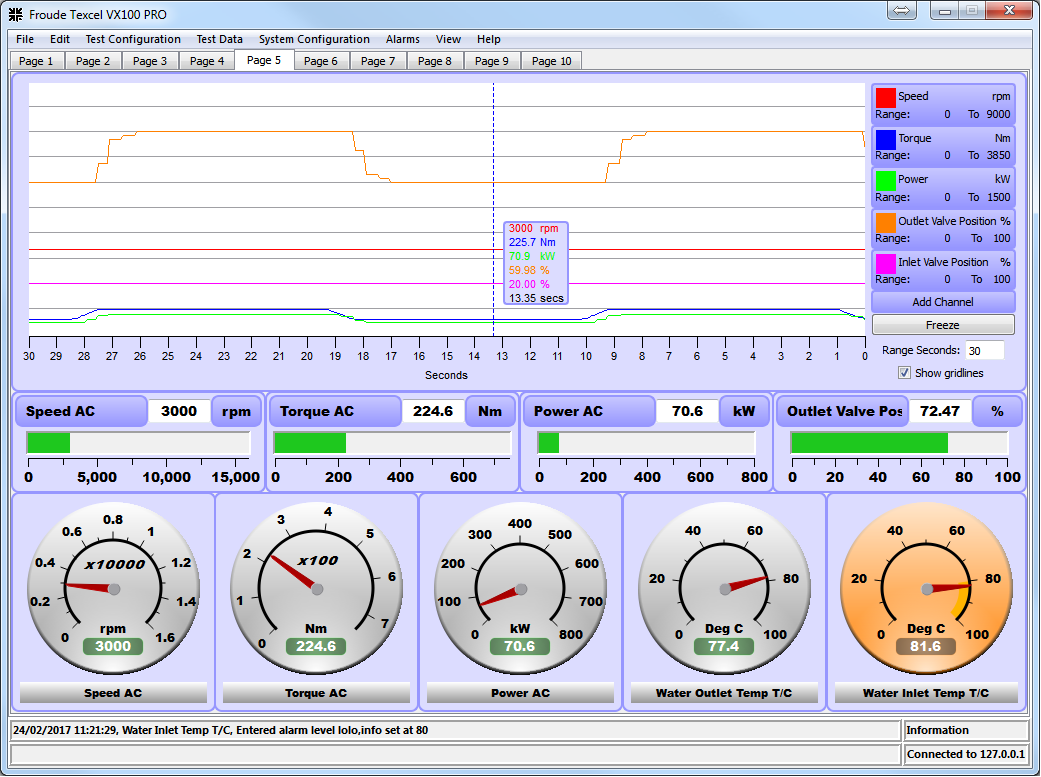

VX100 PRO Controller

The Texcel VX100 PRO Control and Monitoring System is specifically designed for high performance engine and gas turbine test applications using hydraulic dynamometers in R&D, production and post overhaul testing.

The Texcel VX100 PRO Control and Monitoring System utilizes a real time micro-controller to provide fast and accurate load control. This incorporates sophisticated digital control algorithms together with enhanced health monitoring and fault recovery software.

The compact design simplifies installation and makes use of the latest distributed I/O hardware technology.

The operator's control panel provides MS Windows™ based Graphics User Interface with multi page display which can be configured by the user to show numeric, bar chart, dial, and real time rolling trace displays.

For technical data, please download the factsheet